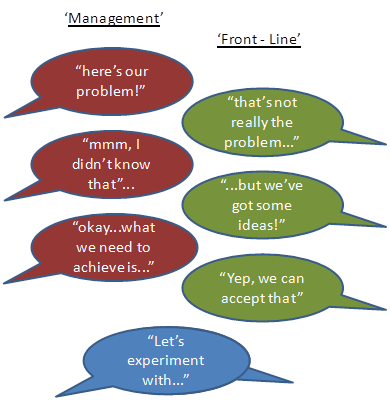

Catch ball: Participative approach to decision-making in which information and ideas are thrown and caught back and forth, up and down throughout the organization”

Catch ball: Participative approach to decision-making in which information and ideas are thrown and caught back and forth, up and down throughout the organization”

(www.Businessdictionary.com)

Jeffrey Liker clarifies further:

“A two-way conversation, not a one-way mandate…[where this is] a real conversation based on facts, not just lip service.”

‘Consultation’

Many a ‘command and control’ organisation will point to (what is known as) their ‘consultation process’ as evidence of their ‘best practise’ in engaging with their employees.

But what is actually happening here?

A solution to a hypothetical/ ideological/ management perceived problem is proposed and released ‘for consultation’;

A solution to a hypothetical/ ideological/ management perceived problem is proposed and released ‘for consultation’;

- Those who notice it then scramble around to alert those that they see as being affected: “hey people, have you seen what’s just gone up on our intranet?!…you’ve got x days to say something about it!”;

- There is much confusion about what the actual problem is, why the solution is proposing such radical ‘silver bullet’ change…and why the people at the coal face weren’t properly asked about it first;

- Some people respond (many ‘choose‘ not to), FAQs are crafted, the consultation period ends, and a ‘finalised’ solution is issued (i.e. it becomes ‘organisational law’) and everyone is thanked for their contributions that brilliantly demonstrated [insert ‘corporate attitudes’ here]

- …and if required, the sponsor of the ‘solution’ then employs some ‘change manager’ to force it through and, hey presto, all sorted!

If the first (real) step in supposed consultation is for an organisation’s management to issue a solution to a problem, and if that solution is then ‘finalised’ after the consultation period is closed then this is a one-way mandate masquerading as meaningful collaboration.

‘We need each other’

The above is not saying that there isn’t a role for management when making improvements. Indeed there is, but a radical different one than has become the norm.

Management’s job is to be very clear on customer purpose, on the value streams required to deliver against this, and how each value stream is performing against its purpose (i.e. its capability) and then to facilitate the front-line (value creating) workers through constant improvement.

The front line worker’s job is to constantly increase their competency in delivering value to their customers, and through this, know where in the process needs improvement.

…and, together, management and front line worker can pull improvements to where they are most needed ‘at the gemba’ and work through a logical 2-way problem solving method.

Implicit in the above is management’s number 1 task: to create, and sustain, a positive, collaborative environment in which each and every person is intrinsically motivated to fully engage and grow, towards a mutually agreeable purpose.

Consensus through ‘Catch ball’

The word ‘Consensus’ means agreement reached by a group. However, Liker expands this meaning within a Toyota context:

“Consensus does not mean that everyone agrees – that would be impossible.

“Consensus does not mean that everyone agrees – that would be impossible.

Consensus at Toyota means that each person feels that he/she has been respectfully heard, and that his/her ideas have been seriously considered.

A leader tests, modifies, and improves a proposal at all levels of the organisation before it gets [put forward].”

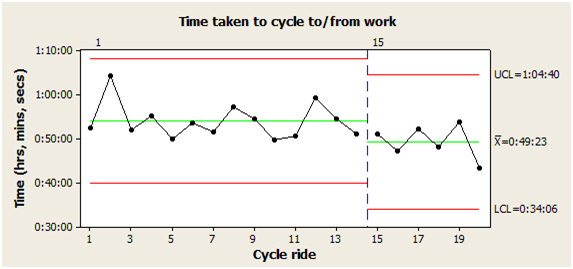

This means that it starts with clarity on the problem, through understanding of the facts…it proceeds through 2-way conversations, engaging in real discussions, experiments and innovation…and it culminates in consensus.

But won’t this take ages?!

Well, yes and no. This is to ‘go slow to go fast’.

Imagine if every change made was supported from the moment it is put in place! Think of all the cr@p that would be avoided. Think of how everyone would feel, and therefore how energised they would be to get involved, to come up with ideas, to listen to and consider alternatives to the status quo.

Use knowledge not opinions!

So, on looking at the above method, here’s a concern from management: “We have to accept that this is a really large organisation. We’d love to listen to all our people but every time we ask for their opinions we get hundreds of different, and contradictory, ideas! We simply can’t satisfy everyone all of the time.”

No, you can’t….so, to clarify: Don’t solicit opinions (like talk back radio). Start with and always come back to the facts!

…and if you’re not sure about something, don’t guess – go back and look deeper.

Start with a clear and meaningful challenge

Now, the ‘consensus’ bubble conversation above is better than the ‘consultation’ one…but it still starts with management suggesting the problem to the front line.

Let’s go one step further – Management should start with a very clear challenge (where this is a meaningful step towards the customer purpose) and then, through facilitation, help the workers identify the problems.

“But why would the workers do this?” I might hear you ask…well, yes, they will only do this if their environment is such that they are intrinsically motivated to do so. Remember that Turkeys don’t vote for Christmas.

Management should:

- Be absolutely clear on purpose (of the system in focus);

- Study the system at the gemba so as to truly understand its current condition (collect the facts, get knowledge);

- Set the next challenge (the target condition – the end state to be achieved);

- Facilitate the value-creating workers through experimentation towards the challenge;

- ….and when achieved, set the next challenge – and repeat.

Rather than waiting for problems to arise, it is far better to “get your butt to the gemba and anticipate them” (Bicheno).

The truth – can you handle it?

The truth – can you handle it?

To end on a related point:

Many an organisation attempts to craft corporate communications and manage their people’s voices such that everything appears to be ‘on message’. Displays of ‘incorrect’ attitudes are frowned upon (and guarded against).

This means that, through the behaviours that this then creates, management cannot know the truth.

Contrast this with Toyota leaders who go out of their way to see and feel dissonant data. They want to know reality and most certainly don’t want to succumb to believing in a dream world!

A favourite quote of mine:

“If you cannot argue with your boss, then he [she] is not worth working for.” (Deming quoting Lt General Leslie E. Simon)

This is not championing anarchy. This is simply pointing out that if you are ‘in management’ and:

- your people do not regularly and passionately challenge you; or if they do

- you firmly argue with them ‘towards your way of thinking’

…then you are commanding and controlling your way to a soul-less wilderness.