I’ve been meaning to write this post for 2 years! It feels good to finally ‘get it out of my head’ and onto the page.

I’ve been meaning to write this post for 2 years! It feels good to finally ‘get it out of my head’ and onto the page.

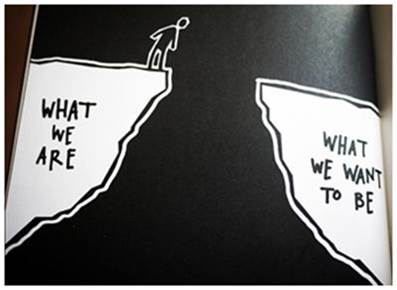

It’s about that lovely ‘Transformation’ word.

Before I go on, I’ll repeat a definition from an earlier post:

“Transformation: In an organisational context, a process of profound and radical change that orients an organisation in a new direction and takes it to an entirely different level of effectiveness….transformation implies a basic change of character and little or no resemblance with the past configuration or structure.” (businessdictionary.com)

To repeat the key phrase: An entirely different level of effectiveness! …and, just in case you missed it, the word is effectiveness, not efficiency.

I’m going to outline 3 levels of (supposed) transformation and I’ll do this by borrowing the bones of an idea from Mike Rother’s excellent ‘Toyota Kata’ book and extend it with a large dose of my own ‘poetic license’.

Level 1 Transformation: ‘On the surface’

So, picture the scene: It’s the late 1970s. Your organisation desperately wants to improve and, on looking around for someone achieving brilliant results, you spot the awesome Toyota (or such like1).

So, picture the scene: It’s the late 1970s. Your organisation desperately wants to improve and, on looking around for someone achieving brilliant results, you spot the awesome Toyota (or such like1).

You go on a Toyota factory visit. You are amazed at what you see and excitedly ask them how they do it.

You easily observe (‘on the surface’) lots of obvious methods and tools…and so you grab evidence of how these are carried out – e.g. some template forms, and the instructions that go with them. You also take lots of pictures of their (visual management) walls to show all this working in situ.

You run back home, hand out the methods and tools and mandate that, from now on, this is what we are doing.

You helpfully provide training and (so called) ‘coaching’…and you put in place ‘governance’ to ensure it’s working. You roll it all up together and you give it a funky title…like your Quality Toolbox. Nice.

You helpfully provide training and (so called) ‘coaching’…and you put in place ‘governance’ to ensure it’s working. You roll it all up together and you give it a funky title…like your Quality Toolbox. Nice.

So what happens?

Well, yep, those tools and methods sure are ‘shiny new’ and easily applied. There’s an initial buzz, probably because of senior management focus…and pressure to prove the comedy ‘Return on Investment’ (ROI) calculation that had to be set out in the short-term thinking ‘will you pay for our factory trip?’ business case.

But the initial effects fall away. Anything achieved was a one-off, or of limited and low level benefit. The changes aren’t sustained – with a slide back to the old state. People start to misuse the tools and methods, and do much damage rather than good. There is a brief and ugly fight with the ‘methods and tools’ compliance police but disillusionment sets in and the early good work becomes discredited and abandoned (just like the last silver bullet…and the one before that…)

Timely reminder: “A fool with a tool is still a fool” (Grady Booch)

Note: This ‘on the surface’ transformation attempt has been likened to organisations going over to Japan in the late 1970s and early 1980s and coming home to fanatically ‘do Total Quality Management’ (TQM)…and then quietly dropping it a few years later. Sure, some organisations sustained it but most didn’t.

Level 2 Transformation: ‘Under the skin’

So it’s now the 1990s. The methods and tools that came out of the initial Toyota factory visit weren’t sustained but the pressure is still on (and mounting) to transform your organisation…and your management can’t help noticing that Toyota are still doing amazing!

So it’s now the 1990s. The methods and tools that came out of the initial Toyota factory visit weren’t sustained but the pressure is still on (and mounting) to transform your organisation…and your management can’t help noticing that Toyota are still doing amazing!

“Perhaps we didn’t look hard enough or close enough or long enough…perhaps we should go back and have a look ‘under the skin’.”

…and so you go for another factory visit (once you’ve been given permission following another well written story business case 🙂 ).

This time you take real care – studying ‘at the gemba’ for weeks, asking questions, watching activities, understanding the nature of changes being made to the system before you.

“Eureka! There’s something underneath those methods and tools! We can see that there’s an underlying logic that we missed last time round…oooh, we could codify them into a set of principles!”

And here’s basically what you arrive at:

0. Everything should belong to, or support, a value stream (a horizontal flow from customer need, through to its satisfaction)

…and for each value stream we should:

1. Specify value, where this is through the eyes of the customer; then

2. Identify all the actions performed within the value stream, and expose and remove the obvious waste; then

3. Create flow by understanding and removing the barriers; then

4. Establish pull by producing only what is needed, when requested; and finally

5. The ‘golden nugget’: we should continually strive for perfection because this is a never-ending journey

Wow, that was profound – your factory tour team now need to give it a name!

And so, after a fun focus group, a young member of your team called John2 shouts out “It needs less of everything to create a given amount of value, so let’s call it ‘Lean’.”

Whoop, whoop, he’s only gone and cracked it!

You run back home to tell everyone about the wonders of ‘Lean’. You hand out books, provide training courses, coaching and mentoring and you slot all those wonderful tools and methods nicely into their place…neat…this is going to be great!

So what happens?

Well, everyone absolutely LOVES the principles. They make sooo much sense. They particularly liked playing with Lego in the training sessions to demo flow, pull, kanban and ‘stop the line’ thinking.

But after a while (and some short-term gains) you realise that there’s a huge tension building. No one can make those darn principles work because they continually clash with existing management practises.

Your senior management employ a gaggle of so-called Lean coaches to try to change the people at the bottom whilst they carry on at the top as before!

Your ‘Lean Office’ has become an island of coaches doing great work with the people but unable to turn the tide. Coaching conversations end with responses like:

“Yes, I can see that would be the right thing to do for the value stream…but that’s not what my objectives, performance rating and bonus is based on…or what my manager above me would support…so I’ll stick to soul-destroying fighting within my silo. Sorry about that 😦”

This culminates in huge frustration; a revolving door of broken coaches; and many a good employee finding a better organisation to work for. If you ran an employee survey at this point, the results would make for ugly reading – you’ve created a complete divide between worker reality and management ‘cloud cuckoo land’.

Oh, and that lean word? Well it became capitalised! LEAN…as if it were a thing. You’ve all forgotten that it was just a label thought up by John in a focus group merely to describe what the factory visit team saw.

Pause for reflection: Taiichi Ohno is considered to be the father of the Toyota Production System (TPS) but he didn’t want it to be written down3 (codified) because he wanted it to remain dynamic.

And as for that name:“Ohno did not call his innovation ‘lean’ – he didn’t want to call it anything. He could, perhaps foresee the folly of a label.” (John Seddon)

Caution: …and if you did this ‘under the skin’ (supposed) transformation within a service organisation, you may find (if you properly stood back to look at it!) that you’d totally f@ck$d it up!

Credit: The ‘Level 2’ principles jotted down above are the core of the 1996 book ‘Lean Thinking’ by Womack and Jones….which they wrote following their research in Japan. They explicitly set out 5 principles, with a foundational one implied (hence why I’ve labelled it as ‘principle nought’).

Level 3 Transformation: ‘In the DNA’

…and so to the 2000s. The pressure to change your organisation is relentless – the corporate world is ‘suffering’ from seemingly constant technological disruption…but Toyota continues to be somehow different.

…and so to the 2000s. The pressure to change your organisation is relentless – the corporate world is ‘suffering’ from seemingly constant technological disruption…but Toyota continues to be somehow different.

You pluck up the courage and ask for a sabbatical for 6 months – you want to find the meaning of life…well, perhaps not that deep…but you sure as hell want to know what Toyota have got that you don’t…and to work this out, you are going to have to go in deep – to their DNA.

Toyota are happy to see you again. But, rather than repeating what you did on the last two trips, you come straight out with it:

“Okay, you’ve shown me your tools and methods…you’ve let me uncover your principles…and I know that these aren’t the answer! What are you hiding from me?! Come on, I get it, it’s a competitive world out there but PLEASE let me in on your secret.”

The Toyota managers are perplexed. They don’t know what else they can do. They are adamant that they aren’t hiding anything from you.

…and so, rather than go straight back home empty handed, you ask if you can work with Toyota to experience what day-to-day work is actually like. They humbly agree to your request.

And six months later your mind has been totally blown!

You really get it….no, REALLY GET IT!

You couldn’t see the wood for the trees but now it’s as obvious as can be.

It’s all about the environment created by management’s actions, which come from their beliefs and behaviours about human beings: about society, about customers…and, most profoundly, about employees.

This is invisible on a factory visit! But it’s still there. It’s simply ‘in the DNA’.

Sure, you could provide a list of attributes as to what this looks like…but management can’t just do them, they have to believe in them – in fact, ‘be’ them!

Further, there’s nothing to be ‘implemented’ because it can’t be!

Everything flows from management’s beliefs and behaviours: It’s from these that Toyota creates new principles, methods and tools all the time…and throws out old ones that are no longer appropriate. Their systems thinking and human thinking is solid and profound, whilst their method is dynamic and agile.

…and the realisation sinks in: No wonder Toyota are happy to open their door to anyone. The thing that makes them great can’t be copied. It has to be lived and breathed…and nurtured from the shop floor all the way up. Oh sh1t!

…and so to your new headache: you totally ‘get it’ but how on earth do you change your organisational system – now that is THE nut to crack. That would be transformational!

Reflection time:

So ‘On the surface’, ‘Under the skin’ or ‘In the DNA’: What level of transformation are you playing at?

…if you are at level 1 or 2 then it’s not actually transformation.

…if you are truly at level 3, then here’s the final mind blowing bit – it is self-sustaining.

To close: I have been asking myself a HUGE question for a fair while now: Can management’s beliefs and behaviours change within a large floating (i.e. short-term thinking) shareholder owned organisation. I’m nearly there with writing down my thoughts. Watch this space…

Footnotes:

1. Just Toyota? I use Toyota in this story since everyone knows who they are…and visits to their factories is precisely what happened regularly over the last several decades. But it isn’t just Toyota.

Your own ‘Toyota’ factory visit could be to another great organisation…and it needn’t be a factory making products – it could be a service organisation. Handelsbanken would be a great financial services example.

Though beware, there aren’t that many ‘true Toyotas’ out there. And perhaps none that have sustained it for so long.

2. ‘John’: He’s even called John in the true story – John Krafcik, a young researcher on Womack’s MIT research team…and those were his words back in 1987 (as recalled by Womack) to give birth to the Lean label.

3. Writing it down: Ohno finally relented when he retired in 1978 and wrote a book on TPS.

4. Clarification: I think a great deal of Lean Thinking, but not a lot about ‘LEAN’ – the implementation movement. I respect Womack and Jones, and their writings…but I note that my favourite Womack book is ‘Gemba Walks’ written about a decade after ‘Lean Thinking’ in which he humbly reflects that it was about far more than the tools and the principles. It was really about the management system (or, in my words, the DNA).

Are you interested in crossing that divide?

Are you interested in crossing that divide?