Warning (or advert for some): Sometimes I write long(er) ‘foundational’ type posts – this is one of them 🙂

Warning (or advert for some): Sometimes I write long(er) ‘foundational’ type posts – this is one of them 🙂

Russ Ackoff researched and wrote a great deal about systems.

It is within his writings1 that I find an excellent explanation about why many organisations adopted the command and control management model, why there is a major problem with this and, most importantly, why there is a better way.

First, A recap:

Before looking at types of systems, I should allow Ackoff to remind us what is meant by ‘a system’ and why this matters:

“A system is a network of inter-dependant components that work together to try to accomplish the aim of the system…

The two key pieces here are that:

- there is an aim; and

- it is made up of parts that need to work together (either directly or indirectly) to achieve that aim

If you have parts but no aim then you don’t have a system…you simply have a ‘collection’.

If you have a part that (truly) isn’t required to achieve the aim then it isn’t actually part of the system…which is why your ‘appendix’ body part got its name.

…If each part of a system, considered separately, is made to operate as efficiently as possible, the system as a whole will not operate as effectively as possible…

The heart and lungs are parts of the body but if they function according to what’s best ‘for themselves’ then they won’t function as required for the overall good of the whole. It’s no good if the brain is telling the heart and lungs to ‘work flat out’ to run like hell from a chasing pack of lions and these organs both respond with a “no thanks, this doesn’t suit us!” The same is true for parts of (e.g. functions within) organisations.

…The performance of a system depends more on how its components interact than on how they act independently of each other…

You can buy a ‘light as a feather’ carbon frame, an awesome set of aero wheels and a precision engineered 11-speed group set but you can’t ride them as a bike if they don’t fit together. Further, someone with a basic ‘sit up and beg’ bike frame with cheap wheels and components that do fit will easily beat you in a bike race.

…When a system is taken apart it loses its essential properties.”

If you take apart an alarm clock, you will have all of the parts necessary for the system but the disassembled collection of parts isn’t sufficient to tell you the time.

The above has huge implications.

So, on to Ackoff’s system types:

Ackoff defined a number of types of systems2 and the problems that occur when an organisation adopts a management model that does not match the correct system type.

Here goes….

Type 1: Deterministic (e.g. mechanisms)

A deterministic system is one which has no purpose and neither do its component parts. This might seem rather strange…”Erm, I thought you said a system had to have an aim?!” – the point is that a deterministic system normally serves a purpose of an entity external to it, such as its creator. Its function, and that of its parts, is simply to provide that service when required.

A deterministic system is one which has no purpose and neither do its component parts. This might seem rather strange…”Erm, I thought you said a system had to have an aim?!” – the point is that a deterministic system normally serves a purpose of an entity external to it, such as its creator. Its function, and that of its parts, is simply to provide that service when required.

Mechanisms are the most obvious examples of deterministic systems: An alarm clock is such a system. Its purpose (to tell the time) has been provided to it by its creator (the clock maker)….and that is what it is for, nothing more and nothing less. It can’t decide to do something else!

Even a computer, whilst incredibly more complicated than an alarm clock, is such a system – it is reliant on the inputs and programs provided to it by its external sources.

Type 2: Animated (e.g. most organisms)

An animated system is one which does have a purpose of its own but its parts don’t.

An animated system is one which does have a purpose of its own but its parts don’t.

Animals (and therefore humans) are the most obvious example. They have a purpose of their own – where this might be argued as (at a minimum) survival, and (more optimistically) to enjoy doing so, in the manner of their own choosing.

The animal is made up of parts (e.g. organs) and whilst these parts have a necessary function for the good of the whole, they do not have a purpose of their own.

In this way we can compare a computer to a person and see that they are fundamentally different. The computer’s purpose is provided to it whilst the person provides their own.

Type 3: Social (e.g. organisations, societies)

A social system is one which has a purpose of its own and so do its parts (the people within).

A social system is one which has a purpose of its own and so do its parts (the people within).

Indeed each social system is usually part of a larger social system (e.g. a family is part of a community, which is part of a nation, which is part of ….)

And even more complex, a person belongs to multiple social systems – which have different, sometimes conflicting, purposes3.

So, bringing these three types together, we have:

| System Type4: |

The whole is: |

The Parts are: |

| Deterministic (e.g. a mechanism) |

Not purposeful |

Not purposeful |

| Animated (e.g. a human) |

Purposeful |

Not purposeful |

| Social (e.g. an organisation) |

Purposeful |

Purposeful |

These three system types form a sort of hierarchy: The deterministic alarm clock is given purpose by the animated (clock making) person who also lives within their social group. The linkages don’t go the other way….or at least they shouldn’t…which leads on to…

Okay, interesting stuff but what’s the point?

Well, now that we have an understanding of three different types of systems, we can see the consequences of the misunderstanding of an organisation as a system:

A ‘deterministic’ model applied to an organisation:

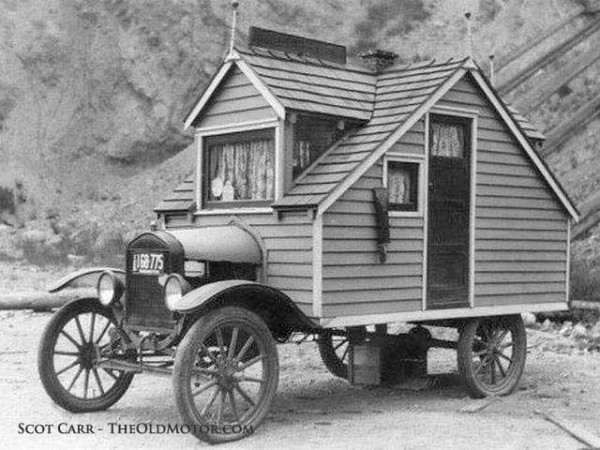

Adam Smith (often referred to as the father of economics and of capitalism) wrote a famous book called ‘The wealth of nations’ (1776). In it, he used the example of a pin factory to explain the concept of ‘the division of labour’. He explained that one person performing all the steps necessary to making a pin could perhaps make only 20 pins a day but if the pin-making process were broken up into a series of limited operations, with separate people performing them in a joined-up line, productivity could rise to thousands of pins per day per worker.

Now that sounds fantastic doesn’t it! But for who?

Smith’s thinking was taken on board by industrialists who went on to employ vast factories of ‘unskilled labour’ in the new concept of ‘manufacturing’ (and who likely still do in the sweat shops of 3rd world countries).

Standing back, we can see that this is using people as replaceable machine parts i.e. we have a defined mechanism (the manufacturing process) which is given its purpose externally by its creator (e.g. make pins)…and wow, this mechanism sure can make pins!

Henry Ford’s phenomenal success worked in the same way. He designed a mechanism to make Model T Fords (his mass production factory) and installed workers as the mechanism’s parts. He (and other ‘owners’ at this time) could use workers in this mechanistic way because:

- unskilled workers, whilst poorly educated, were adequate for the simple tasks required of them;

- such workers were willing to tolerate being treated as a machine part since there was high unemployment and virtually no social security safety net…giving them little option (i.e. work as required or starve);

- there was a large pool of available labour – the human parts of the machine were easily replaceable; and

- such business owners were subject to very little societal controls (such as governmental interventions and constraints) limiting their treatment of their worker ‘parts’4.

It’s worth noting that, even though worker conditions were massively in his favour, Ford’s ‘mechanism’ had an astounding 370% turnover of workers in 1913, with new hires staying an average of only 3 months. Many workers simply ‘walked off the job’ without notifying anyone…which is what happens if you ask humans to perform monotonous (demoralising) work without having to use their brains.

An ‘animated’ model applied to an organisation

So times moved on. We had two world wars that caused/ enabled major societal changes – a major shakeup of the class system, the birth and rise of the Labour movement and worker unions, massive improvements in education, social security and welfare, and great advances in technology.

The other significant change was the raising of capital (necessary for post war growth and development) from the public and the consequent birth/ rise of publically owned corporations. This separated the ownership and management of these new organisations.

A big difference from before was that:

- the workers were now far more educated and empowered; and

- the required work had become far more skilled (utilising new technologies).

Managers were no longer able to treat workers as merely replaceable cogs in a machine – it took time to train them, and they now had worker rights and choice.

Now, rather than seeing an organisation as a deterministic system with the all-powerful owner dictating its purpose (as the likes of Ford had done), they operated as an animated system would6: with a ‘brain’ (senior management) and a ‘body’ (the various operating functions performing the work).

Such a model works by senior management providing the instructions (the what: commands) and procedures (the how: controls) and then the operating units carrying them out accordingly.

“Command and control represents the division of labour between decision-making and doing the work.” (Seddon)

We all know that the ‘operator’ parts within the organisations ‘body’ are actually human beings but the ‘command and control’ management instruments don’t really recognise this fact:

- the organisational ‘brain’ (often annually) decides the strategy and breaks this down into a set of objectives for the parts of the ‘body’ and locks these into a cascaded grand plan;

- the organisational ‘brain’ provides incentives for the ‘body’ to act as it requires: thus assuming that it is simply a matter of extrinsically motivating each part to comply as required;

- the organisational ‘brain’ considers the performance of each part of the ‘body’, scores it and delivers this judgement back: thus assuming that each part can and will accept such feedback for the good of the whole;

- the organisational ‘brain’ performs (frequent) reorganisations on the ‘body’ parts, as if shifting pawns around a game board. The brain does this by dictating such redesigns to the body rather than asking the body if (and how) it could better rearrange itself;

- The organisational ‘brain’ thinks that the answer to an increasingly complex environment is simply to increase the quantity and regularity of communication with the ‘body’ parts. This fails to realise that communication is not the underlying problem.

But the reality for every organisation is that they have purposeful parts – you and I – whether they like it or not…and so to treat these parts as merely having a function for the whole is to inevitably generate conflict.

A social model applied to an organisation

…and so we reach the point at which we conclude the obvious that:

AND

- the humans working within it have separate purposes.

…and therefore any management model that doesn’t understand and work within such a social system will be very limiting – causing loss of immeasurable value to the organisation AND to the people within.

Now you might say “okay, interesting stuff, but treating an organisation as an animated system and using command and control methods has worked fine so far…why do we need to change?”

The rate of change in our world has been massively accelerating. It used to be that change was seen as generational and this made it relatively easy for people to adapt but this no longer holds true.

Organisations are operating in more complex and less predictable environments with the result that:

“Over the last 50 years, the average lifespan of S&P 500 companies has shrunk from around 60 years to closer to 18 years.” (Source: The art of corporate endurance )

Here’s a classic Deming quote: “It is not necessary to change. Survival is not mandatory.”

But if survival is desired, then the best chance that an organisation has is to operate a management model that actually fits with the correct type of system! In so doing, it can get the best out of everyone within.

What might this model look like? Studying ‘Deming’s 14 points for Management’ would be a great start. A post to follow next.

Who’s been successfully operating a social model for decades? Two brilliant examples are Toyota and Handelsbanken.

Footnotes:

1. Credit: The core of this post comes from learnings derived from a classic Ackoff essay entitled ‘Reflections on systems and their models’ which can be found in the book ‘Ackoff’s Best: His classic writings on management’.

2. I’m aware that other system thinkers have created other, more sophisticated, classification schemes (e.g. Boulding, Beer). Ackoff’s system types nicely serve the purpose of this post.

3. This fact is probably relevant to the need for, and creation of ‘soft systems thinking’…which is where Peter Checkland’s work fits in (A ‘giant bio’ currently in draft)

4. For those ‘system’ geeks out there: Ackoff explained a 4th system type, that of an ecological system – where the parts are purposeful but the whole is not. Ecological systems contain interacting mechanistic, organismic and social systems, but do not have a purpose of their own. However, their function(s) serve the purpose of the systems that are their parts.

Example: the purposeful use of fluorocarbons as propellants by humans (a purposeful part of the ecological system) affects the ozone layer in a way that is determined, and not a matter of choice for our planet (the whole)…the planet cannot decide that it is harmful to it and decide to ‘do something about it’– the outcome (even though we may not understand it) is determined.

5. Henry Ford realised the problem and, in an attempt to compensate for their conditions, paid his workers well as compared to what they could earn elsewhere.

6. Stafford Beer wrote a famous book called ‘The brain of the firm’ (1972) that explored in detail the analogy of an organisation working as the human body does.

My experiences and understanding (i.e. my mental model) of the world is (incredibly) limited. That wasn’t a confession – so is yours 🙂

My experiences and understanding (i.e. my mental model) of the world is (incredibly) limited. That wasn’t a confession – so is yours 🙂

I have bought and read a fair few ‘management books’ over the years. Some start off usefully but go on to ‘wind me up’, others are absolute diamonds….and so I had a little think about why this might be.

I have bought and read a fair few ‘management books’ over the years. Some start off usefully but go on to ‘wind me up’, others are absolute diamonds….and so I had a little think about why this might be. I wrote a post some months back (July 2016) titled

I wrote a post some months back (July 2016) titled  Colours: Yes, I can see a number of sources that refer to different colours. However, I would suggest splitting the colour story into three parts (each of which Andrew’s comment eludes to):

Colours: Yes, I can see a number of sources that refer to different colours. However, I would suggest splitting the colour story into three parts (each of which Andrew’s comment eludes to):

Getting back to the point within my original ‘River Rouge’ post – that of handling variety in the line:

Getting back to the point within my original ‘River Rouge’ post – that of handling variety in the line: Andrew’s comment on my original post provided me with the impetus to learn some more.

Andrew’s comment on my original post provided me with the impetus to learn some more.

Warning (or advert for some): Sometimes I write long(er) ‘foundational’ type posts – this is one of them 🙂

Warning (or advert for some): Sometimes I write long(er) ‘foundational’ type posts – this is one of them 🙂 A deterministic system is one which has no purpose and neither do its component parts. This might seem rather strange…”Erm, I thought you said a system had to have an aim?!” – the point is that a deterministic system normally serves a purpose of an entity external to it, such as its creator. Its function, and that of its parts, is simply to provide that service when required.

A deterministic system is one which has no purpose and neither do its component parts. This might seem rather strange…”Erm, I thought you said a system had to have an aim?!” – the point is that a deterministic system normally serves a purpose of an entity external to it, such as its creator. Its function, and that of its parts, is simply to provide that service when required. An animated system is one which does have a purpose of its own but its parts don’t.

An animated system is one which does have a purpose of its own but its parts don’t. A social system is one which has a purpose of its own and so do its parts (the people within).

A social system is one which has a purpose of its own and so do its parts (the people within).

Problem: (supposed hoards of) illegal Mexicans

Problem: (supposed hoards of) illegal Mexicans On 23rd June 2016 Britain votes on whether to remain in or leave the EU.

On 23rd June 2016 Britain votes on whether to remain in or leave the EU. So it seems that many an organisation repeats a mantra that we must “simplify, simplify, simplify”…they accompany this thrice repeated word with rhetoric that implies that this is so blindingly obvious that only a fool would query this!

So it seems that many an organisation repeats a mantra that we must “simplify, simplify, simplify”…they accompany this thrice repeated word with rhetoric that implies that this is so blindingly obvious that only a fool would query this!

“The righter we do the wrong thing, the wronger we become. When we make a mistake doing the wrong thing and correct it, we become wronger.” (Russell Ackoff)

“The righter we do the wrong thing, the wronger we become. When we make a mistake doing the wrong thing and correct it, we become wronger.” (Russell Ackoff)