I wrote a post some months back (July 2016) titled ‘The River Rouge – A divergent legacy’. If you haven’t read it, then it is necessary context for this post.

I wrote a post some months back (July 2016) titled ‘The River Rouge – A divergent legacy’. If you haven’t read it, then it is necessary context for this post.

I received an interesting comment at the end of the post (from a contributor called Andrew) as follows:

“You’re perpetuating an inaccurate myth about the Model T and production at Highland Park. The Model T was produced with tremendous variation – far more than a modern car. There were at any given time at least six different body styles of Model T, representing a lot more complexity than a simple color change. http://www.curbsideclassic.com/wp-content/uploads/2011/02/Ford-Model-T-line-up-1911ad-lg.jpg

As to color, the Model T was available in several colors – but not black – in its early days when the production rates were low. Black was introduced, not to minimize variation, but because black paint dried quicker and enabled faster, higher production rates. By 1926, paint science matured to the point that six additional colors were introduced to go along with black (and better compete with Chevrolet).”

I replied to Andrew’s comment and promised that I would add an addendum1…and then, as is usual, life carried on and time flew by. It is now, in this quieter Christmas/ New Year period that I realise that I have a hole to plug.

So here goes…

Correction

My original post, whilst (in my view) highly positive of what Henry Ford achieved, used the enduring “you can have any colour you like, as long as its black” line. I used this as the strap line to observe that “[Ford’s] manufacturing process was not designed to handle variety”, as explained in separate books by H. Thomas Johnson and Mike Rother.

My post then went on to contrast two very different approaches to handling the variety conundrum.

Andrew’s comment pointed out that the Model T was available:

- in more than one colour; and

- with different body styles.

He went on to suggest that “The Model T was produced with tremendous variety – far more than a modern car”.

Colours: Yes, I can see a number of sources that refer to different colours. However, I would suggest splitting the colour story into three parts (each of which Andrew’s comment eludes to):

Colours: Yes, I can see a number of sources that refer to different colours. However, I would suggest splitting the colour story into three parts (each of which Andrew’s comment eludes to):

The early years (1908 – 1914): From cross-checking a number of Ford related websites, it would appear that the Model T was available in a small variety of colours during its early low-level production years (grey, green, blue and red).

The volume years (1914 – 1926): This period corresponds to breakthrough improvements in producing at scale (and reducing the price)….and the only colour available was black.

In his 1922 ‘My Life and Works’ autobiography Ford refers to his salesmen wanting to cater for their customers’ every whim, rather than explaining that the product already satisfies their requirements…and it was this exchange that caused his “so long as its black” idiom:

“Therefore in 1909 I announced one morning, without any previous warning, that in the future we were going to build only one model, that the model was going to be “Model T”, and that the chassis would be exactly the same for all cars, and I remarked: “Any customer can have a car painted any color that he wants so long as it is black.”

Reference is made across a number of sources that black paint was used because its fast-drying properties aided speedy production. Other reasons suggested are the cheap cost of black paint, its durability and ease of reapplication (e.g. when repairing).

The end (1926 – 27): Colour choices were reintroduced…but this can be seen as an attempt to prop sales up and fight off the inevitable death of the Model T:

“Alfred Sloan [General Motors] began to offer inexpensive Chevrolets with amenities that the Model T lacked…..the market began to shift…styling and excitement suddenly counted to the customer.

But Henry Ford refused even to consider replacing his beloved Model T…only one person persisted in warning him of the impending crisis: his son, Edsel…it was the first of many arguments that Edsel would lose.

The Chevrolet continued to take sales from the dour Model T. By 1926, T sales had plummeted, and the realities of the market place finally convinced Henry that the end was at hand. On May 25th 1927, Ford abruptly announced the end of production for the Model T.” (Forbes Greatest Business Stories of All Time)

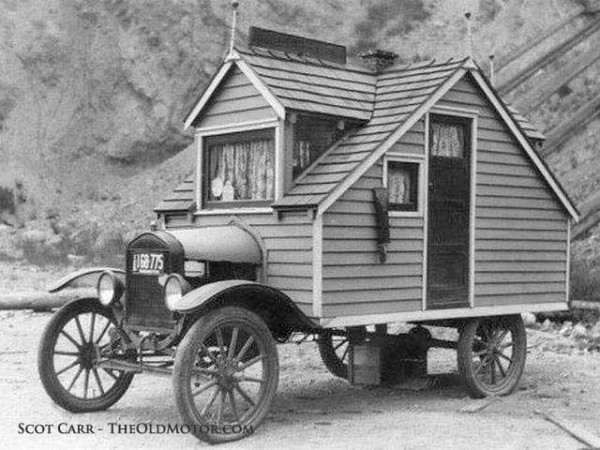

Body styles: Andrew’s comment usefully provides a link to an image showing a number of different Model T body styles, though I note that the title refers to 1911 which sits within the ‘early years’ pre-mass production period.

Breaking the body styles comment into a few parts:

The chassis: The Model T Ford was made up of the chassis (see title picture of this post) and then a body connected on to it.

From what I have read (including Ford’s words), the key point about the Model T Ford was that the chassis ‘moving down the line’ were all the same. Sure, they would differ over time as the design was (regularly) improved, but not ‘in the line’.

I find the picture below quite interesting – it shows2 a long line of Model T chassis waiting for a body (of differing styles) to be lowered on to it from a side process. Note the overhead rail coming in from the right.

Factory Bodies: Yes, I can see that different bodies were available – as can be made out from examining the above picture – but there was a limited range of standard designs (e.g. the Tourer, Roadster, Coupe and Sedan3).

You might ask “but what about all those other body styles out there?”…

Aftermarket ‘engineering’: You can come across all sorts of weird and wacky looking vehicles all around the world that have been built on a Model T chassis. This is unsurprising given the sheer volume (and market share) of Model T’s that were out there.

A fair bit of ‘reconfiguring’ occurred, with owners hacking the car apart and customising it for their own needs. Many specialist aftermarket companies sprang up to perform conversions, even maturing to selling prefabricated kits for specific purposes, such as tractors. If you want a laugh at the sorts of conversions carried out then have a look at some of the images here (including a tank, a camper van…and a church!).

So, yes, I do need to correct my previous post’s implication that you could only ever buy a black Model T, and that one Model T was exactly the same as any other.

There was some variety, but does that mean Henry Ford had built a manufacturing process specifically aimed at handling this? And so I move on to….

Clarification

Getting back to the point within my original ‘River Rouge’ post – that of handling variety in the line:

Getting back to the point within my original ‘River Rouge’ post – that of handling variety in the line:

Andrew’s comment of “The Model T was produced with tremendous variety…” might imply that Ford had indeed solved the variety riddle. I don’t think that this is the case and I’ll use a couple of passages from Ford’s own 1926 ‘Today and Tomorrow’ book to illuminate why I believe this:

“Whenever one can line up machinery for the making of exactly one thing and study everything to the end of making only that thing, then the savings which come about are startling.” (Chapter 5)

“The strongest objection to large numbers of styles and designs is that they are incompatible with economical production by any one concern. But when concerns specialize, each on its own design, economy and variety are both attainable. And both are necessary…

…we believe that no factory is large enough to make two kinds of products. Our organisation is not large enough to make two kinds of motor cars under the same roof.” (Chapter 7)

An underlying philosophy of Ford’s tremendous production success was a standard product (i.e. the opposite of variety)…which nearly became his undoing and set his organisation onto a path of catch-up with General Motors from the late 1920s onwards.

…none of this takes away from what Ford achieved and what then happened in American manufacturing and, in contrast, across the world in Japan. To summarise:

- Henry Ford made amazing advances in respect of manufacturing, but the Model T’s homogeneity became its Achilles heel (a fact that he eventually conceded to his son Edsel and to his competitors);

- In general, American manufacturing from the 1950s onwards went in the direction of scale and ‘unlearned’ much of what Ford had shown them; whilst

- Toyota (learning from Ford) carried on in the direction of flow and worked out methods of handling variety in the line…thus achieving great things.

It’s worth reflecting that Taiichi Ohno credits Henry Ford with Toyota’s foundations:

“Taiichi Ohno…always spoke glowingly of Ford’s achievements…In 1982, Philip Caldwell, then head of Ford Motor Company, visited Japan. When Caldwell asked Eiji Toyoda, head of Toyota Motors, where Toyota had learned the production methods they employed so successfully in the 1970’s, Toyoda replied, ‘there’s no secret to how we learned to do what we do, Mr Caldwell. We learned it at the Rouge.’” (Johnson, quoting from David Halberstam’s ‘The Reckoning’)

Continual Learning

Andrew’s comment on my original post provided me with the impetus to learn some more.

Andrew’s comment on my original post provided me with the impetus to learn some more.

- I entered into a useful dialogue with Tom Johnson and Mike Rother;

- I bought and read Ford’s book ‘Today and Tomorrow’;

- I read around (and cross-checked) a fair bit of internet content; and

- …I pondered what all of that lot meant.

I reflect on a wonderful Ackoff quote:

Although being taught is an obstruction to learning, teaching is a marvellous way to learn!”

i.e. it is in the act of attempting to explain something to others (e.g. via a post) that we can truly learn.

(I believe that) I now know more…but I’m even more certain that there’s much more to learn. A never-ending journey 🙂

Footnotes

1. Writing an Addendum: I am mindful that a number of you may have read my original post but not seen Andrew’s comment or my reply. So, rather than allowing this to remain somewhat hidden, I thought it only right (and respectful of Andrew’s fair and useful comment) to elevate my response* to a further post.

(* I am not a fan of the ‘gutter press’ splashing scandalous statements across their front pages, only to publish a unapologetic, one-line ‘retraction’ in tiny text somewhere buried on page 13)

2. Using photos: I am mindful that Ford’s production processes changed all the time and I have been warned to be careful when using a black and white picture of Model T production methods – such a picture shows how it worked at a point in time…and could easily have changed radically very soon afterwards!

3. Body Styles information taken from http://www.fordmodelt.net/model-t-ford.htm. It shows that each of the main body styles evolved over time e.g. the Touring car went from 2 doors from 1909, to 3 doors from 1912 and then 4 doors from 1926.

…and I just have to add a picture of (what I understand to be) a Model T chassis with a body style of a house – definitely ‘after market’:

I’ve been meaning to write this post for 2 years! It feels good to finally ‘get it out of my head’ and onto the page.

I’ve been meaning to write this post for 2 years! It feels good to finally ‘get it out of my head’ and onto the page. So, picture the scene: It’s the late 1970s. Your organisation desperately wants to improve and, on looking around for someone

So, picture the scene: It’s the late 1970s. Your organisation desperately wants to improve and, on looking around for someone  You helpfully provide training and (so called) ‘coaching’…and you put in place ‘governance’ to ensure it’s working. You roll it all up together and you give it a funky title…like your Quality Toolbox. Nice.

You helpfully provide training and (so called) ‘coaching’…and you put in place ‘governance’ to ensure it’s working. You roll it all up together and you give it a funky title…like your Quality Toolbox. Nice. So it’s now the 1990s. The methods and tools that came out of the initial Toyota factory visit weren’t sustained but the pressure is still on (and mounting) to transform your organisation…and your management can’t help noticing that Toyota are still doing amazing!

So it’s now the 1990s. The methods and tools that came out of the initial Toyota factory visit weren’t sustained but the pressure is still on (and mounting) to transform your organisation…and your management can’t help noticing that Toyota are still doing amazing! …and so to the 2000s. The pressure to change your organisation is relentless – the corporate world is ‘suffering’ from seemingly constant technological disruption…but Toyota continues to be somehow different.

…and so to the 2000s. The pressure to change your organisation is relentless – the corporate world is ‘suffering’ from seemingly constant technological disruption…but Toyota continues to be somehow different. I often hear people talking about the need for profit and that my thinking must address this fact. I respond that it does, but not as they might think. This post tries to explain.

I often hear people talking about the need for profit and that my thinking must address this fact. I respond that it does, but not as they might think. This post tries to explain. Are you interested in crossing that divide?

Are you interested in crossing that divide?